Description

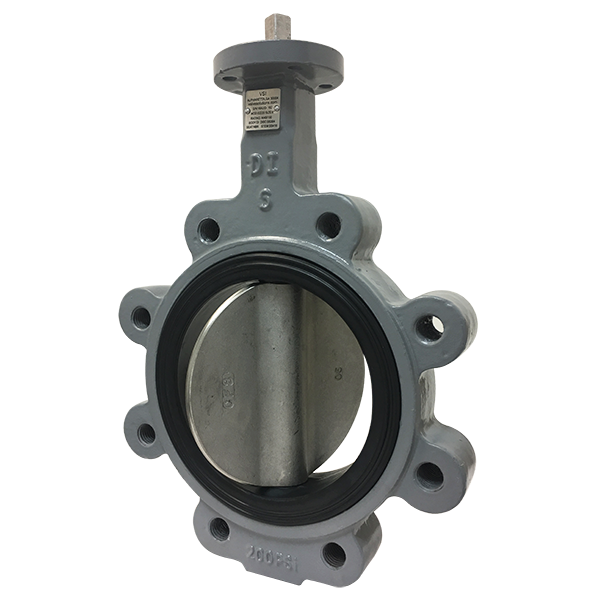

Butterfly Valve (Series 2100)

- Stem design: Available in square shaft for easy mounting of actuators, levers and gear operators.

- Top flange: Conforms to ISO 5211 for the mounting of actuators, levers and gear operators.

- One piece shaft: Maintains disc position.

- Resilient seat surface: Eliminates the need for gaskets on flanges.

- Shaft pins: Enables a vibration free connection between the shaft and the disc.

- Bi-directional secured seat: Phenolic backed seat is bi-directional and blow out proof.

- O ring seal: Provides a seal to interior stem and bushings.

- Bushings: Provide correct alignment of shaft through the body and reduces torque.

- Stem seal: Positive seal in both directions to prevent leakage.

- Disc edge: Smooth finished disc edge provides superior seal, reduces valve torque and provides bubble tight shutoff.

- Bi-directional body & seat design: Suitable for bi-directional use at full rated pressure.

- Backed seat support: Prevents stem leakage and high valve torque from poor installation.

- Dead end service option: Available with special dead end service option that allows installation of valve on discharge/intake pipes with no downstream pipe or flange.

Downloads:

Application Data Sheet – Fill Out and Return for Accurate Quote