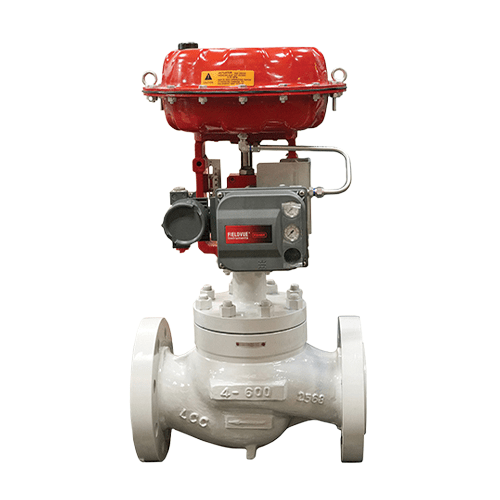

Description

SIZES

- 1/2″ – 24″

BODY MATERIAL

- A216

- WCB

- 304

- 316

- Alloys

TRIM MATERIAL

- 304

- 316

- Alloys

CV RATIO

- 30:1 (Tendril)

- 50:1 (Reduced Cage)

- 100:1 (Full Cage)

END CONNECTIONS

- Flanged

- BW

- SW

- ANSI 150-2500

TEMPERATURE RANGE

- -22°F to +1049°F

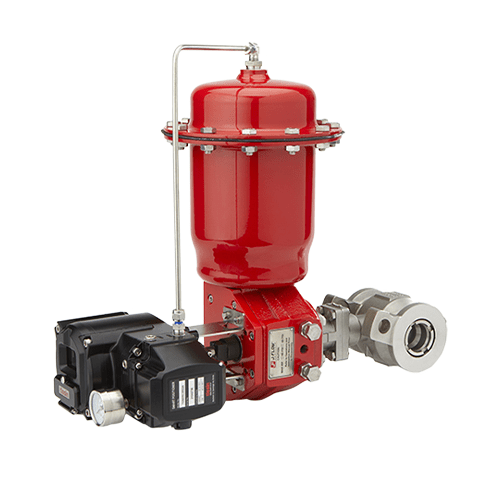

I & M

4000 Series I & M

870 & 880 Diaphragm Actuator Manual

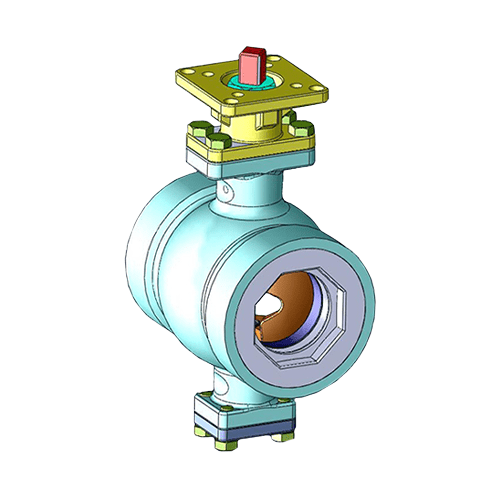

OVERVIEW

J Flow Control Valve & Butterfly Product Overview

J Flow Automation Capabilities Overview